FAILURE SUPPLY CHAIN ANALYSIS AND ITS CORRECTIVE ACTIONS

-Dr.D.Sathishkumar

Assistant Professor

Sankara Institute of Management Science(SIMS)

INTRODUCTION

Operational superiority in consumer returns management, failure analysis and closed loop curative actions is captivating on an progressively more important position as companies endeavor to get better in their business processes, policies and supply chains to accomplish a outstanding management position in their industry. When redesigning the supply chain designs the premeditated decisions require to be complete concerning supply chain designs that are associated with the hallucination of the endeavor. High tech companies are looking for prepared development with customer satisfaction and life cycle fabricate distinction gratifying a determined improvement, high apparatus companies are provoked to appear away from their chronological spotlight on advance supply chains for better operational and financial performance. Equipped superiority in customer returns management, failure analysis, and closed loop corrective actions are the innovative focus for companies annoying to achieve competitive improvement and an outstanding guidance situation in supply chain management. In this article it illustrates the failure analysis and the disputes presently faced by high tech companies in management and highlighting the failure analysis supply chains. The method for improving the failure analysis supply chain and the curative proceedings for failure analysis supply chain and creating comprehensive conclusions. The intent of the endeavor is to highlight the failure analysis supply chain challenges faced by high tech companies and distinguish approaches to surmount these in a victorious approach.

SUPPLY CHAIN ANALYSIS FAILURE

High tech companies will fabricate problematical products to their electronic customers. These products might be shipped to one of the companies to distributors to consumers or to retail supplies where consumers can acquire products. If these products get damage or any manufacturing problem these products are contacted to the manufacturing company and it is send to the company after transaction or liberation this procedure is called reverse logistics.

Some general complaints met by the companies when the customers return their products:

- The products are not to their expectations or change of product which is not ordered.

- The Goods are defective or damage at the period of transport when the customer receive the product.

- Product fails due to some constraints made by users or due to some technical fault in the warranty period.

- Getting back the products for some manufacturing faults identifies by the competitive company product.

- Recycle the product with local government regulations by the company

Products are return due to damage, defects or operational failures, it is important for companies to understand the root cause for this failure. The purpose of diagnosing faults within the returned units and determining root cause is called failure analysis. The complex network of sites, partners, IT applications and processes that supports failure analysis is called the failure analysis system. Failure analysis often involves visual inspection of the returned unit, mechanical and electrical testing of the part and sometimes disassembly to identify and evaluate the cause and severity of the failure. By understanding nature of the product failure, the repair organization can correct the fault with the unit and either return the unit to the customer or hold the unit as a replacement for another warranty situation.

High tech companies can provide feedback to the development organization to prevent or reduce the effect of such problems in future designs of the product. This feedback can also provide similar problems from arising with other customers. In some cases, contacts with the end customer may require the manufacturer to provide information on the root cause of the problem to ensure that the customers network to electronic instruments that does not disturb the communication system. The process of understanding the root cause of failure, correcting the fault, and feeding information back to the other parts of the organization and customers is often referred to as closed loop corrective action.

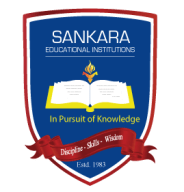

Figure 1: Failure analysis system information

The process shown in figure 1 is high level representation of failure analysis system. The main difficulty factors experiential in large international companies comprise:

- Product family and Numerous products

- Physically detached clients and downstream supply chain associates

- Numerous websites and outsourced associates in different physical locations

- Numerous enervates of failure analysis sites

- Insufficient gate keeping information for influential authority of proceeds

- Dissimilar systems to handle information

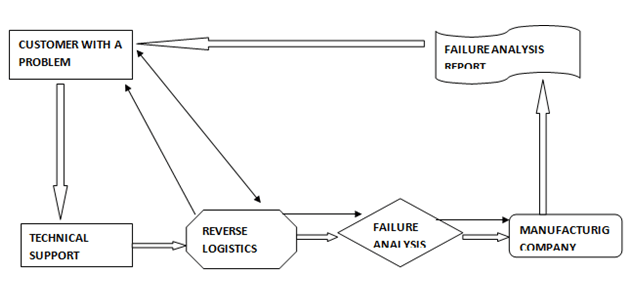

Figure 2: Product and Information Flow Failure In global

THE FUTURE FAILURE SUPPLY CHAIN ANALYSIS

The high tech companies are forced to relocate on prepared effectiveness in the whole supply chain as well as with the functions of reverse supply chain, it is more important and can analyze the solution for new failure analysis supply chain architecture and it helps to solve the problems and can find the ways to identify the values for the function to be achieved. In this article it illustrates the gap between present and future conditions of the supply chain.

FINDING THE VISION FOR FAILURE SUPPLY CHAIN ANALYSIS

At the present time companies had known the significance of mission and vision statements to support the human resources and stakeholders approximately the objectives of the company and guarantee that each person focuses the actions on accomplishing the vision. Likewise the company can describe a vision for personality organization and to cross functional business processes like failure analysis supply chains. A vision declaration to facilitate the company’s assurance to higher consumer approval and a optimistic consumer understanding supports the diverse, dissimilar stakeholders with in the failure analysis supply chain approximately a common objective of ensuring that consumer will remain at the forefront of every grouping actions. By bringing mutually a variety of stake holders groupings in important the vision, the company can make sure that every group consents with the vision and is dedicated to implement to accomplish the vision.

CLASSIFYING THE GAP AMONG PRESENT AND FUTURE SUPPLY CHAIN ANALYSIS

The gap analysis would engage formative where the developments and approaches from the present condition would need to modify consecutively to meet the needs of the prospect state. Failure analysis supply chains undergo from high costs. Failure analysis stakeholders wish to inferior cost and cut down processes. Thus the gap among present state and future state can be recognized as they transmit to the cost drives of the failure analysis supply chains. Whereas detailed approaches and accomplishment changes to concentrate on there gap are not the main focus of this segment, a high tech company might absolute the procedure. These thoughts would be utilized to expand execute plans to re design meticulous aspects of the failure analysis supply chain.

PREVIOUS APPROACH OF FAILURE SUPPLY CHAIN ANALYSIS

Regular endeavor architecture has been considered by several intellectuals in the management and societal discipline fields for a numeral of existence. Conversely the majority of this exertion has been accepted out with a extraordinary focus on IT system procedure views, and architect organizations. Companies to assist include try to designer or revamp their systems and organizations, tended to regard as the process, organization structure, background, information technology in separation, and make improvements to everyone individually.

An advanced level loom to architect the failure analysis supply chain absorbs:

- Identifying and understanding the failure of supply chain analysis in the present

- Categorize the vision for the opportunity to get failure in supply chain analysis

- Considering the problems in the present classification and the gaps among the present and preferred state

- Finding probable clarifications or advances to final the gaps

- Selecting between option move towards and suggests an loom

A FRAMEWORK FOR REVERSE SUPPLY CHAIN

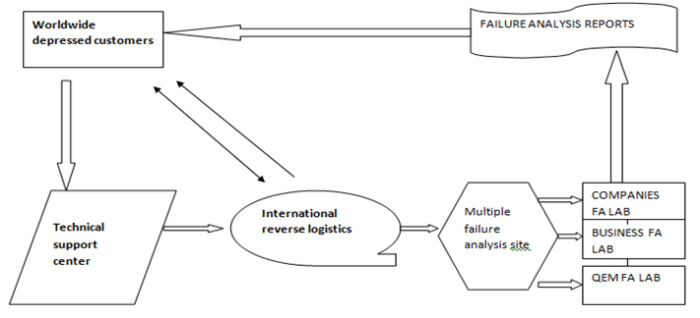

Figure3: Reverse supply chain architecture

SUPREMACY

The supremacy view believes the endeavor business model, business plan, interior and exterior strategies that impact the endeavor, arrangement among policies, plan and organization, management of the production, incessant development and propose principles relates within the industry.

DEVELOPMENT

The development view considers input processes and behavior within the reverse supply chain. It comprises that the process are directly concerned in the gate keeping of the products and belongings, attainment of the products back from consumers, reverse logistics operations, temperament of the products returned to the company and recuperation of value from the products. It is also includes management of the uninterrupted process and consumer experience and processes for monitoring the functions.

REPEAL SUPPLY CHAIN PROPOSAL

The repeal supply chain proposal design view considers the endeavor from the perception of scheming the supply chain arrangement. This comprise network design of the supply chain, optimization of the supply chain, reverse logistics design, record management, financing behavior and outsourcing connected decision making. This distinguish the function of network has foremost insinuations for its cost configuration benefit expenditure discharge lead period, faithfulness, receptivity, limberness, consumer services and its companies financial appearance and dissimilar system structures have dissimilar strengths and weakness.

ASSOCIATION

Association is used to recognize the possession and arrangement of the association within the endeavor, configuration across the association and enlightening fundamentals involved with management a cross functional association.

POSSIBLE TECHNOLOGY

Possible technology includes the hardware, software, infrastructure and information management systems that sustain the endeavor. In the circumstance of the reverse supply chain, this probable expertise observation considers procedure computerization, visibility, knowledge systems.

PERFORMANCE MANAGEMENT

Performance management considers the organization and bench marking processes and organizations necessary to direct the business. It moreover includes the key performance pointers that are significant to calculate contained by the reverse supply chain endeavor. It allows the endeavor to calculate the achievement of some new or redesigned procedure.

CHOOSING THE BEST SUPPLY CHAIN DESIGN BY USING ASSESSMENT MODEL

In all the associations pronouncements are made on a repeated foundation at all levels:

- Premeditated

- Equipped

- Planned

Pronouncements are made through concerning the direction of the firm, the suppliers to form relations with, which consumers order to accomplish, etc. Whereas several conclusions are pinnacle downward more and more conclusions are completed at inferior levels in the organization. The direction approach within association often decides where in the disagreement, in which numerous decisions makers converse the pros and cons of the resolution or agreement in which every associate of the conclusion making grouping agrees to execute the decisions. Resolutions making might happen using together debate and consensus. Many high tech firms frequently use debate to recognize the pros and cons of the problems concerned in the resolution, agreement is not constantly emphasized. Moderately the conclusion of the resolution plays an ever more significant role. Dedication from members in a cross functional conclusion making players is significantly important in firms that require different organizations or functions to organize with each other and make sure that the suggested action will be implemented, particularly by those who may have unpopular accomplishment. The shares appreciate of foundation will help through implementation, by building momentum to conquer any obstructions that may occur.

FAILURE SUPPLY CHAIN ANALYSIS DECISION MODEL

A failure supply chain analysis decision that absorbs numerous stakeholders groups for input, conversation and accomplishment are not much different. Such resolutions should engage deliberate by the groups that are impacted or will require contributing in the new endeavor planning, and necessary agreement to make sure achievement of the accomplishment of the arrangement and procedure. Decisions completed inside the organizations might be based on intensely embedded assumptions about consumers, organizations, procedure and approaches to convinced behavior generous rise to conservative perception that could be trailed by the firm or complete industries.